Get Brampton commercial cleaning and sanitation experts who follow CSA, WHMIS, and Peel Public Health. You'll get SOPs, SDS access, comprehensive monitoring, calibrated dilution logs, and documented verification. We verify disinfection with ATP/fluorescence, maintain dwell times, and utilize ECOLOGO/Green Seal, DIN/EPA-registered solutions. Teams operate off-peak with security protocols, color-coded tools, and chain-of-custody for disinfectants. Auditable reports, CAPA workflows, and sector-specific protocols (office, retail, healthcare, industrial) come standard. See how we limit interruptions while raising compliance.

Main Insights

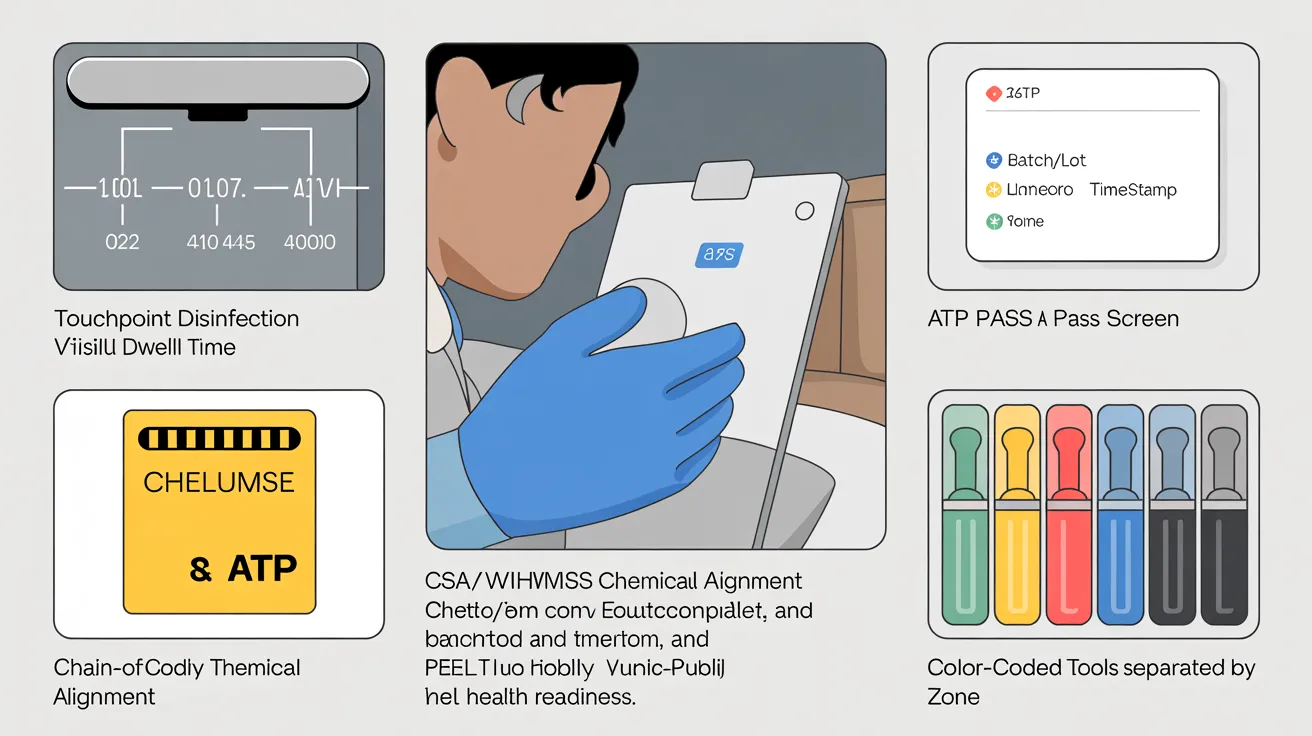

- SOPs aligned with CSA, WHMIS, and Peel Public Health standards with documentation prepared for audits including SDS libraries, lot tracking, and timestamped service records.

- Risk-based sanitation protocol: featuring strategic touchpoint analysis, EPA-approved cleaning solutions, validated contact duration, ATP and fluorescence testing, and scheduled third‑party microbiological analysis.

- Operational precision: employing after-hours operations, compact work units, entry management, secure tracking for chemicals, and controlled distribution with service records.

- Environmental leadership: ECOLOGO and Green Seal certified products, automated dilution technology, advanced microfiber technology, thorough waste evaluations, and ISO 14001-compliant sustainability KPIs.

- Thorough quality assurance with management reviews, CAPA workflows, retraining protocols, and conformity records aligned with insurers, regulators, and Brampton municipal bylaws.

Why Professional Cleaning Matters for Brampton Businesses

Though daily maintenance keeps areas presentable, expert cleaning validates your Brampton premises complies with regulatory, safety, and health standards. It's essential to have established protocols that align with local regulations, verified cleaning products, and precision-tuned equipment to mitigate liability and contamination concerns. Trained professionals implement established cleaning protocols, color-coded equipment, and precise dwell-time controls to guarantee effective pathogen elimination and surface clearing without compromising surface integrity.

You can expect comprehensive assessments that track traffic patterns, touchpoints, and HVAC impacts, then determine specific intervals and quality assurance protocols. Environmental factors are crucial: salt and grit in winter demand doorway washing and matting upkeep; warm season moisture needs dehumidification support and mold prevention; autumn and spring seasons carry airborne particles requiring improved air filtering and elevated cleaning. Comprehensive documentation, chemical information availability, and waste management systems simplify inspections and demonstrate adherence.

Business Segments: Offices, Retail, Healthcare, and Industrial

You need cleaning standards that match business facility standards-touchpoint disinfection, floor care programs, and refuse sorting-while following local health and safety bylaws. For healthcare, you require CSA- and IPAC-compliant procedures, EPA-registered disinfectants, confirmed product application periods, and tracking documentation for biohazard handling. In industrial settings, you expect WHMIS/GHS labeling, safety lockout procedures, particulate filtration systems, and audit-ready SOPs.

Commercial Space Protocols

When operations span across various facilities from offices to retail spaces, healthcare centers, and industrial locations, sanitation procedures need to comply with industry-specific requirements and measurable quality standards. For office and retail environments, you must establish cleaning schedules, procedures, and validation processes by area. Utilize floor plans to chart foot traffic patterns, frequent contact areas, and material specifications, and organize duties according to risk levels. Establish suitable cleaning solutions, concentration levels, and application times; maintain safety data sheet accessibility and equipment calibration records.

Establish staff guidelines for: zone-specific glove protocols, cable management, quiet-hours procedures, and safety signage for accident avoidance. Set up a color-coded system for supplies to avoid cross-contamination in restrooms, break rooms, and public spaces. Organize systematic vacuum maintenance, microfiber system updates, and refuse sorting. Assess outcomes using contamination sampling, documentation systems, and corrective protocols aligned with quality thresholds and customer SLAs.

Industrial and Healthcare Standards

Because of healthcare and industrial environments carry increased risk profiles, we utilize verified procedures that meet regulations and endure audit scrutiny. You receive site-specific Standard Operating Procedures mapped to CSA, Public Health Ontario, and OSHA/WHMIS requirements. We implement color-coded tools, closed-loop chemical dilution, and barcode-logged tasks to guarantee trackability, infection control, and contamination mitigation.

Throughout our medical facilities, we follow Spaulding classifications, conduct terminal cleaning, and employ EPA-registered disinfectants with verified wet contact times. We confirm effectiveness through ATP bioluminescence testing and thorough audit checklists. Areas containing sharps receive puncture-resistant waste disposal and comprehensive chain-of-custody tracking.

Within industrial zones, we coordinate LOTO coordination, combustible dust control, and specialized non-sparking equipment usage. Surface degreasing is performed with slip resistance verification. We calibrate measurement devices, maintain SDS databases, deliver hazard communication instruction, and create compliance reports satisfying your audit protocols and insurer requirements.

Essential Sanitization Guidelines for High-Touch Areas

While routine cleaning clears visible debris, sophisticated disinfection protocols focus on microbial populations on high-touch surfaces with proven, measurable procedures. You should commence with touchpoint identification to document door hardware, rails, switches, faucets, elevator panels, POS terminals, and shared devices. Establish risk tiers, set dwell times per EPA-registered disinfectant, and document material compatibility to avoid surface deterioration. Standardize sequence: preliminary cleaning, application, wet contact maintenance, and validation.

Apply electrostatic distribution for uniform coverage of intricate shapes; fine-tune dispensers, validate droplet size, and control pass speed. Perform rapid hygiene monitoring or fluorescent indicators for real-time validation, and schedule periodic third-party microbiological swabs for outcome validation. Instruct staff on safety equipment protocols, safety information analysis, and inventory control. Log lot identifiers, time records, and personnel codes for compliance preparation and event tracking.

Eco-Friendly Products and Sustainable Practices

You'll choose environmentally-friendly cleaning products that meet ECOLOGO or click here Green Seal standards and adhere to WHMIS and SDS documentation. You'll implement waste management approaches, featuring microfiber systems, dilution monitoring, reusable dispenser systems, and source-separated recycling following Brampton and Ontario guidelines. You'll verify performance with VOC limits, biodegradability requirements, and regular audits to track compliance and ongoing improvement.

Sustainable Cleaning Materials

Implement a higher compliance bar by mandating eco-certified cleaning agents that meet respected standards like ECOLOGO (UL 2792/2795), Green Seal (GS-37/GS-53), or EPA Safer Choice. In your green certification documentation, list the product identifier, certification ID, dilution ratios, pH range, VOC content, and SDS references. Ensure third-party verification on containers and validate listings in each certifier's online registry.

Identify cleaning solutions compatible with microfiber, autoscrubbers, and touchpoint protocols. Specify surfactant systems with rapid biodegradation, NPE-free formulas, and low-aquatic-toxicity ratings. Determine residual thresholds to promote allergen reduction on heavily accessed zones and in IAQ-sensitive zones. Establish precise dosing mechanisms to prevent overuse and preserve ppm accuracy. Instruct team members on contact duration for disinfectant alternatives conforming to Safer Choice's partner criteria. Audit quarterly, analyze residual compounds, and monitor deviations with remedial measures.

Effective Waste Management Approaches

While upholding strict hygiene standards, implement waste reduction by setting up reusable, repairable, and refillable systems across sites. Begin by conducting Waste audits to analyze material streams by mass, contamination metrics, and waste costs per department. Apply results to select long-lasting dispensers, bulk chemicals, microfiber solutions with monitored washing and color-coded bins. Require vendor collection for packaging materials and pallet reclamation.

Integrate composting initiatives for kitchen and break room organics, verifying that disposal liners conform to ASTM D6400 and waste handlers accept them. Calibrate pickup schedules using bin fill-level measurements to eliminate capacity problems and pest infestations. Train personnel with standard operating procedures, visual guides, and regular training sessions. Monitor key performance indicators: waste diversion rates, individual waste output, and incident nonconformities. Document processes to meet city requirements and ISO 14001 specifications.

Smart Scheduling to Limit Downtime

In line with business operations, customizable scheduling guarantees cleaning takes place outside high-traffic times to avoid operational delays and income reduction. You determine specific service windows, backed with after-hours coordination, so staff functions when business activity is minimal. We assess your operating calendar, blackout periods, and statutory holidays, then align service routines to eliminate overlap with deliveries, audits, and maintenance.

To ensure smooth operations, we implement rotating crews and dedicated units with comprehensive task checklists, scheduled workflows, and performance thresholds. Staff members strictly follow noise, odor, and illumination restrictions, and utilize fast-acting formulations to reduce processing times. Access management, equipment custody, and detailed logging procedures guarantee compliance. We carefully document service details, problem resolution, and occurrence tracking to fulfill operational guidelines, labor agreements, and municipal requirements while maintaining productivity.

Deep Cleaning vs. Regular Maintenance: What to Know

Because compliance standards and operational risks vary by task, it's essential to maintain a clear separation between daily maintenance (scheduled cleaning to maintain sanitation levels) and deep cleaning (regular thorough remediation that restores difficult-to-access and critical areas). You'll assign regular cleaning to high-touch surfaces, restrooms, floors, and common tools using certified cleaning solutions, microfiber cleaning materials, and contact-time certified antimicrobial agents. You must record schedules, protective equipment, techniques, and inspection findings.

Schedule comprehensive cleaning as periodic maintenance according to hazard mapping: key zones such as ceilings, ventilation returns, grout areas, equipment backs, drains, and permeable materials. Utilize ATP or fluorescent markers to verify cleaning effectiveness, escalate to HEPA filtration, scale removers, and steam cleaning where biological contamination is possible. Standardize SOPs, color-coding, and tool segregation to avoid cross-contamination. Monitor results, improvement steps, and inspection timing to ensure compliance.

Health and Safety Standards Compliance

Your maintenance plan will only be effective if it meets statutory and industry requirements, so connect every task to specific standards and record proof of conformity. Map each surface, chemical, and method to industry standards and regulatory requirements. Maintain SDS libraries, dilution logs, lot tracking, and equipment calibration documentation. Instruct staff on PPE selection, donning/doffing, and exposure response. Establish color-coded tools and closed-loop chemical systems to eliminate cross-contamination. Arrange internal audits, keep checklists, photos, and corrective actions to drive inspection readiness. Monitor regulatory updates from Peel Public Health and provincial authorities; update SOPs, signage, and risk assessments accordingly. Confirm disinfectant contact times with ATP testing and document results. Restrict access to storage, label secondary containers, and conduct ventilation checks with documented maintenance.

Custom Solutions for Event Aftermath and Peak Traffic Periods

Even with tight cleaning windows during high-traffic times, your facility needs rapid, guideline-driven cleaning solutions that ensures cleanliness levels without operational disruption. You receive strategic mass-gathering cleanup methods that systematically partition zones, evaluate soil conditions, and implement fast-acting treatments verified against ASTM and Health Canada protocols. Our team conducts thorough disinfection of high-contact surfaces like rails, seats, and concessions with DIN-registered agents with verified contact times.

In floor maintenance, we utilize traction-maintaining detergents, mechanically treat paths, and microfiber recovery to reduce re-soiling. Waste streams are segregated per municipal bylaw, with hazardous materials, glassware, and organic waste managed via marked receptacles and tracking. Post event odorcontrol leverages source removal, enzymatic digesters, and MERV 13-18 air filtration to reestablish IAQ benchmarks. Washroom servicing include scale elimination, grout cleaning, and restocking aligned to occupancy projections.

Skilled Professionals and Quality Management Systems

These operational procedures are only effective when trained experts carry out them under a structured QA framework. You count on certified professionals who follow SOPs aligned with CSA, WHMIS, and manufacturer guidelines. Each specialist completes primary and recurring skill assessment on chemical interaction, dwell times, microfiber sequencing, and ATP verification. You require chain-of-custody logs for disinfectants, calibrated meters, and color-coded zone controls to avoid cross-contamination.

The quality assurance process operates in a closed-loop system. Supervisors conduct performance audits using detailed checklists, testing frequently contacted areas through ATP measurements and visual inspections. Quality deviations initiate improvement measures, detailed issue analysis, and competency development. All service proofs are timestamped, including photographic evidence maintained in regulatory archives for pattern evaluation and assessment. Regular quarterly simulations, safety gear fitting assessments, and refresher training modules keep skills fresh and objectively assessed.

Selecting the Perfect Cleaning Service in Brampton

In evaluating a Brampton cleaning partner, look beyond cost and examine verifiable compliance, staffing practices, and quality controls. Confirm WSIB coverage and insurance coverage limits, along with third-party certifications (such as ISSA, GBAC). Obtain operational protocols, chemical inventories with SDS, and machinery upkeep logs. Verify background verification, immunization policies where needed, and adequate management oversight. Ensure certified education on WHMIS, bloodborne pathogen protocols, and regional guidelines, including waste disposal and sharp object protocols.

Evaluate quality assurance frameworks including scheduled audits, contamination detection methods, and CAPA workflows with documented corrective actions. Demand KPI reporting (response times, quality incidents) and problem resolution procedures. Match scope with financial constraints through defined intervals, work schedules, and operational standards. Verify eco-friendly documentation and air handling requirements. Implement contingency plans for contamination events, resource shortages, and facility security measures.

Popular Questions Answered

Understanding Contract Lengths and Cancellation Terms for Cleaning Services

Standard cleaning contracts usually follow flexible monthly or fixed 6 to 12-month durations. These contracts include information regarding scope, KPIs, renewal options, and cost modifications. Cancellation terms typically specify thirty to sixty days' notification for general contract ending, while immediate termination is permitted for major concerns such as safety violations, expired insurance, or nonperformance issues. Premature cancellation usually requires cancellation charges. Make sure notice procedures (paper or digital), correction windows (five to fifteen days), and financial settlement terms are properly outlined to ensure proper adherence.

Can I Get Emergency Spill or Biohazard Cleanup Outside Regular Hours?

Absolutely - we offer emergency response for hazardous material incidents. Just like an emergency signal breaking through darkness, you can expect a rapid dispatch team within 60-90 minutes. Technicians arrive in PPE, set up biohazard containment, shut down HVAC if required, and follow OSHA, WHMIS, and local public health protocols. We record chain-of-custody for waste, carry out ATP verification, and deliver incident reports. Just give phone authorization; we mobilize immediately and charge emergency response fees.

What Vetting and Insurance Protocols Are in Place for Our On-Site Team?

We provide carefully vetted through a comprehensive screening process. We run thorough national and local criminal screenings, verify identity, and confirm right-to-work eligibility. We collect two professional references when we verify employment history and professional track record. Drug testing is conducted as required by client SOPs. All technicians undergo mandatory safety training, WHMIS/OSHA training, bloodborne pathogens education, and site-specific orientation. We ensure annual background re-checks for all staff members. All personnel carry general liability, pollution, and workers' compensation protection; insurance certificates and endorsements are provided upon request.

Can Services Integrate With Building Access Control and Security Protocols?

Indeed. You are able to align operations with your building's access management and security measures through established integration procedures and comprehensive credential management. You'll set up temporary access cards, access-level authorizations, and geographic access limits. We'll enable API or OSDP integrations, audit-log syncing, and visitor access protocols. You'll implement MFA, minimal access rights standards, and verified credential assignment. We'll establish SOPs, emergency procedures, and immediately deactivate permissions upon access requirement updates. You'll obtain compliance reports and security deviation notifications.

How Are Cleaning Tasks and Service Performance Tracked Through Reports and Dashboards?

Get precise control through a KPIs dashboard and mobile logs providing robust, reliable compliance tracking. The system displays live status information, including timestamps, location-tagged check-ins and adherence to service agreements. You can sort information across zones, shifts, and staff and generate detailed audit trails. Users can perform tracking of consumable usage and conformity checking. Secure data management is ensured through structured access management and advanced data protection, while built-in APIs support detailed performance analytics.

Conclusion

You're more than just contracting cleaners-you're investing in a precision tune-up for your facility's health. With precision sanitization for frequently contacted areas, green-certified products, and compliance-ready paperwork, you'll achieve compliance with precision. Adjustable booking ensures smooth operations, while special event recovery solutions eliminate event remnants. Skilled professionals, checklists, and performance reviews ensure reliability. Select a Brampton service that demonstrates adherence, confirms outcomes, and grows alongside you-so your space operates like a professional environment, clean, safe, and regulation-tight.